In 2001, Pacific Coast Producers (PCP) purchased what is now the Woodland Tomato Operation. The plant had formerly belonged to Contadina, and had been purchased by Del Monte Foods. At the time Del Monte sold the operation to PCP, it was a small tomato paste operation. Between July 2001 and the July 2002 processing season, PCP completely reworked the plant to take it from a small paste operation to one of the largest retail tomato canning operations in the world. The plant produces some 250 SKUs of retail and foodservice tomato products, from whole tomatoes to diced, sliced, crushed and stewed, to sauces and paste. PCP has since added more lines and products to the mix, including our new taco simmering sauce and salad ready tomato products. The Woodland plant has focused on sustainability by reducing water use, and recycling byproducts from the operation such as peels, seeds and stems. This facility is currently focusing on reducing greenhouse gases and energy efficiency, to continue our path toward a sustainable future.

Woodland Plant Tour: From Field To Can

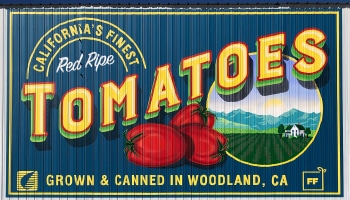

1

95% of our conventional tomatoes are harvested on a PCP family farm, in a field less than 17 miles from our Woodland Tomato Plant

Every load is inpected for defects, color, and character by an independent state grading agency

2

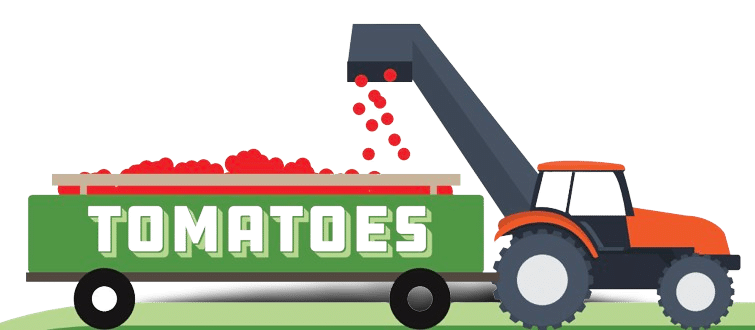

3

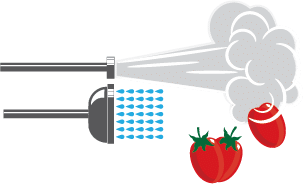

The tomatoes are rinsed and floated out of the truck

Next they are bathed and sent through a steam peeling process

4

5

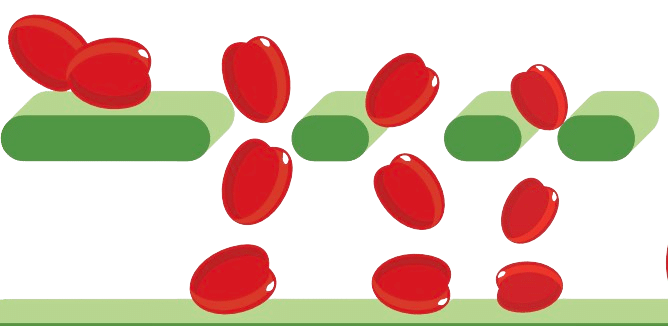

Once steam peeled, tomatoes are brought into the plant and sorted by size and color

Tomatoes are then kept whole, diced, or crushed. Some are made into sauces, paste, juice, ketchup, marinara sauces, pizza sauces, fire roasted, and more

6

7

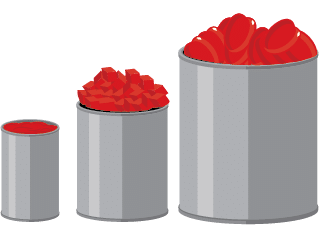

The tomatoes are sorted once again using state of the art technology and placed into different can sizes ranging from 6 oz. to #10 cans

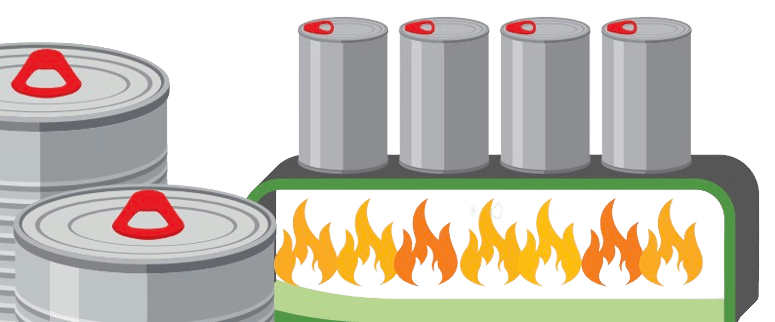

Once canned and seamed they are sent to the giant pressure cookers and are cooked to seal in nutrients

8

9

After cooked and cooled, the cans are reviewed by our QA team to make sure weight, flavor, and other attributes are to our specification

Our canned tomatoes are then sent to our 1.5 million square foot Distribution Center in Lodi, California to await labeling, casing, and shipping

10